A Virtual Visit to The Thompson's Mills Museum and Interpretive Center

|

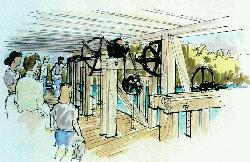

Our guide takes us to an area showing how modern methods of

making flour have changed from pounding grain, to grist mills,

and then roller milling. A special display and model shows the

work of Oliver Evans, inventor of modern industrial automation,

which he applied to flour milling. This was in the year 1787!

Modern technology permits efficient separation of grain into its

components, and then recombination to produce blended and

specialty flours. I learned that soft wheat, as sometimes grown

in the Willamette Valley, makes good donuts and apple pies, but

to make real good bread requires a hard wheat such as grown in Montana and Kansas. Our guide brings us to another area.

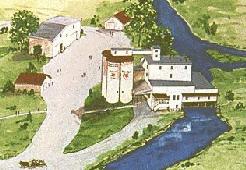

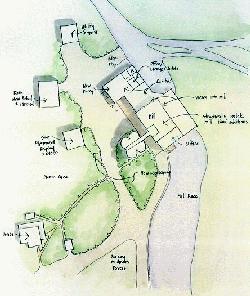

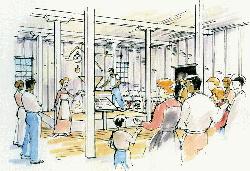

In this area we learn about the history of the old BOSTON MILLS, the town of Boston Mills and the millwrights, millers, carpenters and others who made their home and living right here. The original mill burned down shortly after it was built, but they quickly built a new one. The original mill used the old stone Buhrs. Millers really liked the ones from France because they stayed sharp longer. Sharpening the stones is called dressing, and is done by chipping away furrows in the stone following certain patterns. Later, the stones were removed and replaced with faster machinery called roller mills. And, at the same time other equipment was added for moving grain and flour around as well as cleaning and sifting. When this happened, the name of the mill was changed to BOSTON ROLLER MILLS. Gradually housewives stopped baking bread at home and started buying bread at stores. Fewer and fewer farmers brought their grain here to be ground into flour. Large mills in the city were more efficient, and did not depend on water power directly to operate their machinery. The original mill building was a two and one-half story timber-framed structure using mortise and tenon joints with wood pegs holding them together. Huge logs were harvested near Crawfordsville, and brought here to be shaped into timber using tools called broadaxe and adze. If you look carefully you can see the chopping marks of the adze on some of the old timbers today! The mill now contains three turbines. They are located under water, so a model has been provided to allow one to see how they work. Our guide leads us into the original old Boston Mills. A set of mill stones is set up and the miller shows us how they work. He points out the various parts of the system and describes them by name. Around the walls were old flour sacks, tools and machinery. An old roller mill was there as well as a sifter. Many of the tools were used by millwrights and carpenters to make and repair wooden parts for the mill such as pulleys, chutes and spouts. Our family thought this was the best part of our visit to the old mill. At completion of the demonstration, we went into the outer office and saw photographs of the old mill at various times in its history. We looked into the inner office and saw the old safe that had BOSTON ROLLER MILLS painted on its front with gold paint. Photographs of mill owners, millwrights, millers and carpenters were on the walls. We said good-by to our guide as we left the mill, got into our car and headed back through Shedd and on to our motel in Albany. If we have the time, we can explore a restored natural area, visit a small museum in Shedd, or a larger one in historic Brownsville. Maybe we can do that tomorrow. In the area are some covered bridges that we can visit. It is amazing to see how much things have changed over the years, and that change is still going on! We had a wonderful time at the Thompson's Mills State Heritage Site and will tell all our friends how much fun we had in Linn County, Oregon. |

©opyright 1997- Boston Mill Society